Kuri stade yinganda zikora inganda, ibikoresho byimashini za CNC byahindutse inkingi yumusaruro hamwe nubushobozi bwabo bwo gutunganya neza. Gutunganya neza ibisabwa kubice byingenzi byibikoresho bisanzwe byimashini za CNC ntagushidikanya ko aribintu byingenzi byerekana guhitamo urwego rwibikoresho bya CNC.

Ibikoresho bya mashini ya CNC byashyizwe mubyiciro bitandukanye nkibintu byoroshye, bikora neza, na ultra precision bitewe nuburyo butandukanye, kandi urwego rwukuri ruratandukanye cyane. Ibikoresho byoroheje byimashini za CNC biracyafite umwanya murwego rwubu rwimisarani n’imashini zisya, hamwe n’ibisubizo byibura bya 0.01mm, hamwe no gukora no gutunganya neza muri rusange kuva kuri 0.03 kugeza 0,05 mm cyangwa hejuru. Nubwo ubunyangamugayo ari buke, mubihe bimwe na bimwe byo gutunganya aho ibisabwa bidasobanutse neza, ibikoresho byimashini bya CNC byoroshye bigira uruhare rudasubirwaho kubera inyungu zubukungu nibikorwa byoroshye.

Ibinyuranyo bitandukanye, ibikoresho bya mashini ya ultra precision ya CNC byakozwe muburyo bwihariye bwo gukenera imashini, hamwe nukuri gutangaje 0.001mm cyangwa munsi yayo. Ultra precision ibikoresho bya mashini ya CNC ikoreshwa kenshi murwego rwohejuru kandi rugezweho nko mu kirere nibikoresho byubuvuzi, bitanga ubufasha bukomeye bwa tekiniki yo gukora ibintu bigoye kandi byuzuye bisaba ibintu.

Urebye neza, ibikoresho bya mashini ya CNC birashobora kugabanywa muburyo busanzwe kandi busobanutse. Mubisanzwe, hariho ibintu 20 kugeza 30 byo kugenzura neza ibikoresho bya mashini ya CNC, ariko ibyingenzi kandi bihagarariwe ni umurongo umwe uhagaze neza, umurongo umwe wasubiwemo neza, hamwe nuburinganire bwikizamini cyakozwe na axe ebyiri cyangwa nyinshi zifitanye isano.

Ibirindiro byukuri hamwe nibisubirwamo byukuri byuzuzanya kandi hamwe hamwe byerekana neza imiterere yuzuye yibice byimashini yibikoresho byimashini. Cyane cyane kubijyanye no gusubiramo umwanya uhagaze neza, ni nkindorerwamo, byerekana neza guhagarara kwumwanya wa axis kumwanya uwariwo wose uhagaze. Ibi biranga bihinduka urufatiro rwo gupima niba igiti gishobora gukora neza kandi cyizewe, kandi ni ingenzi kugirango harebwe igihe kirekire cyimikorere yimashini yimashini hamwe nuburyo bwiza bwo gutunganya.

Porogaramu ya sisitemu ya CNC uyumunsi ni nkumunyabukorikori wubwenge, ufite ibikorwa byinshi kandi bitandukanye byindishyi zindishyi, zishobora kwishyura neza amakosa ya sisitemu yakozwe muri buri murongo wurwego rwohereza ibiryo neza kandi neza. Dufashe imiyoboro inyuranye yuruhererekane rwikwirakwizwa nkurugero, impinduka mubintu nko guhanagura, guhindagurika kwa elastike, hamwe no gukomera kwihuza ntabwo bihoraho, ariko byerekana imbaraga zihita zihita zihinduka hamwe nubunini nkubunini bwumurimo wakazi, uburebure bwintera yimodoka, n'umuvuduko wo guhagarara.

Muri sisitemu zimwe zifunguye-zifunguye hamwe na kimwe cya kabiri gifunga ibiryo bya servo, ibice byo gutwara imashini nyuma yo gupima ni nkubwato bugenda imbere mumuyaga nimvura, bitewe nimpanuka zitandukanye. Kurugero, ibintu byo kurambura ubushyuhe bwumupira wumupira birashobora gutera gutembera mumwanya uhagaze wakazi, bityo bikazana amakosa akomeye muburyo bwo gutunganya neza. Muri make, niba hari amahitamo meza mugikorwa cyo gutoranya, ntagushidikanya ko ibikoresho bifite ibihe byiza cyane byasubiwemo neza bigomba gushyirwa imbere, bikongerwaho ubwishingizi bukomeye mubwiza bwo gutunganya.

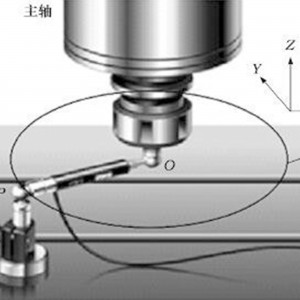

Ubusobanuro bwo gusya hejuru ya silindrike cyangwa gusya ahantu hatandukanye (insanganyamatsiko), nkumutegetsi mwiza wo gupima imikorere yigikoresho cyimashini, nikimenyetso cyingenzi cyo gusuzuma byimazeyo servo ikurikira ibintu biranga icyerekezo cya CNC (amashoka abiri cyangwa atatu) hamwe ninshingano ya interpolation ya sisitemu ya CNC igikoresho cyimashini. Uburyo bwiza bwo kumenya iki kimenyetso nugupima uburinganire bwuburinganire bwa silindrike yatunganijwe.

Mu myitozo yo guca ibice byikizamini ku bikoresho bya mashini ya CNC, gusya kwa oblique kare kwane uburyo bwo gutunganya impande enye nazo zigaragaza agaciro kayo kihariye, gashobora kumenya neza imikorere yukuri kumashoka abiri ashobora kugenzurwa mumurongo wa interpolation. Mugihe ukora iki gikorwa cyo guca ibigeragezo, birakenewe ko ushyiraho witonze urusyo rwanyuma rukoreshwa mugutunganya neza kuri mashini ya mashini, hanyuma ugakora urusyo rwitondewe kurugero ruzengurutse rwashyizwe kumurimo. Kubikoresho bito bito kandi biciriritse, ubunini bwikigereranyo kizenguruka hagati yama pound 200 na 300. Uru rutonde rwageragejwe mubikorwa kandi rushobora gusuzuma neza imikorere yimashini igikoresho.

Nyuma yo kurangiza gusya, shyira witonze urugero rwaciwe kuri metero izenguruka hanyuma upime uburinganire bwubuso bwakorewe hakoreshejwe igikoresho cyo gupima neza. Muri ubu buryo, birakenewe kwitegereza no gusesengura ibisubizo byapimwe. Niba hari urusyo rugaragara rwo gusya rwerekana uburyo bwo gusya hejuru, biratuburira ko umuvuduko wa interpolation wigikoresho cyimashini ushobora kuba udahungabana; Niba uruziga rwakozwe no gusya rugaragaza amakosa agaragara ya elliptique, akenshi byerekana ko inyungu za sisitemu ebyiri zishobora kugenzurwa na sisitemu ya interpolation itajyanye neza; Iyo hari ibimenyetso byahagaritswe kuri buri cyerekezo gishobora kugenzurwa cyerekezo cyerekezo cyerekezo cyumuzingi (nukuvuga, mugukomeza gukata, guhagarika kugaburira ibiryo kumwanya runaka bizakora igice gito cyibimenyetso byo guca ibyuma hejuru yimashini), ibi bivuze ko guhanagura imbere no guhinduranya umurongo bitigeze bihinduka muburyo bwiza.

Igitekerezo cya axis imwe ihagaze neza yerekana ikosa ryakozwe mugihe uhagaritse ingingo iyo ari yo yose. Ninkaho itara, rimurika muburyo butaziguye ubushobozi bwimashini zikoreshwa mumashini, bityo ntagushidikanya kuba kimwe mubimenyetso bya tekiniki byingenzi byerekana ibikoresho bya mashini ya CNC.

Kugeza ubu, hari itandukaniro riri hagati yamabwiriza, ibisobanuro, uburyo bwo gupima, nuburyo bwo gutunganya amakuru yuburyo bumwe bwerekana neza neza mubihugu kwisi. Mu kumenyekanisha ubwoko butandukanye bwibikoresho bya mashini ya CNC byintangarugero, ibipimo rusange kandi byavuzwe cyane harimo ibipimo ngenderwaho byabanyamerika (NAS), ibipimo byasabwe n’ishyirahamwe ry’abanyamerika bakora imashini zikoresha imashini, Ikidage cy’Ubudage (VDI), Ikidage cy’Ubuyapani (JIS), Umuryango mpuzamahanga w’ubuziranenge (ISO), n’igihugu cy’Ubushinwa (GB).

Muri aya mahame atangaje, ibipimo byabayapani biroroshye cyane kubijyanye namabwiriza. Uburyo bwo gupima bushingiye kumurongo umwe wamakuru atajegajega, hanyuma ubigiranye ubushishozi ukoresha ± indangagaciro kugirango ugabanye ikosa igice. Nkigisubizo, imyanya ihamye yabonetse hakoreshejwe uburyo busanzwe bwo gupima ikiyapani akenshi itandukana inshuro zirenze ebyiri ugereranije nibindi bipimo.

Nubwo andi mahame atandukanye muburyo bwo gutunganya amakuru, yashinze imizi mubutaka bwibarurishamibare kugirango asesengure kandi apime neza aho imyanya ihagaze. By'umwihariko, kubintu runaka byerekana umwanya wikosa mugushobora kugenzurwa nigikoresho cyimashini ya CNC, igomba kuba ishobora kwerekana amakosa ashobora kubaho mugihe cyibihumbi byigihe cyo guhagarara mugihe kirekire cyo gukoresha ibikoresho byimashini mugihe kizaza. Ariko, bigarukira kubintu bifatika, akenshi dushobora gukora gusa umubare muto wibikorwa mugihe cyo gupima, mubisanzwe inshuro 5 kugeza kuri 7.

Urubanza rwukuri rwibikoresho bya mashini ya CNC ni nkurugendo rutoroshye rwo gukemura ibibazo, bitagerwaho nijoro. Ibipimo bimwe byukuri bisaba kugenzurwa no gusesengura neza ibicuruzwa byatunganijwe nyuma yimikorere nyayo yimashini yimashini, nta gushidikanya ko byongera ingorane nuburemere bwurubanza.

Kugirango tumenye neza ibikoresho bya mashini ya CNC byujuje ibyifuzo byumusaruro, dukeneye gucukumbura byimazeyo ibipimo nyabyo byibikoresho byimashini kandi tugakora isesengura ryuzuye kandi rirambuye mbere yo gufata ibyemezo byamasoko. Muri icyo gihe, ni ngombwa kugira itumanaho rihagije kandi ryimbitse no guhanahana amakuru hamwe n’abakora ibikoresho bya mashini ya CNC. Gusobanukirwa urwego rwibikorwa byakozwe nuwabikoze, ubukana bwingamba zo kugenzura ubuziranenge, hamwe na serivisi yuzuye nyuma yo kugurisha birashobora gutanga ishingiro ryingenzi ryo gufata ibyemezo.

Mubikorwa bifatika, ubwoko nukuri kurwego rwibikoresho bya mashini ya CNC nabyo bigomba gutoranywa mubuhanga kandi bushyize mu gaciro hashingiwe kubikorwa byihariye byo gutunganya nibisabwa neza mubice. Kubice bifite ibyangombwa bisabwa cyane, ibikoresho byimashini zifite sisitemu ya CNC igezweho hamwe nibice bisobanutse neza bigomba kwitabwaho mbere nta gushidikanya. Iri hitamo ntiritanga gusa ubuziranenge bwo gutunganya, ahubwo rinatezimbere umusaruro ushimishije, rigabanya igipimo cy’ibicuruzwa, kandi rizana inyungu nyinshi mu bukungu ku kigo.

Byongeye kandi, ibizamini bisanzwe no gufata neza ibikoresho bya mashini ya CNC ningamba zingenzi zokwemeza gukora igihe kirekire kandi kigakomeza ubushobozi bwo gutunganya neza. Muguhita umenya no gukemura ibibazo bishobora kuba ukuri, ubuzima bwa serivisi bwibikoresho byimashini burashobora kwagurwa neza, bigatuma umutekano uhoraho kandi wizewe. Nkokwitaho imodoka yimikino yo kwiruka, gusa kwitonda no kuyitaho birashobora gukomeza gukora neza kumurongo.

Muri make, ubunyangamugayo bwibikoresho byimashini za CNC nigipimo kinini kandi cyuzuye cyo gusuzuma, kinyura mubikorwa byose byo gushushanya ibikoresho byimashini no gutezimbere, gukora no guteranya, kwishyiriraho no gukemura, kimwe no gukoresha buri munsi no kubitaho. Gusa mugusobanukirwa byimazeyo no kumenya ubumenyi nubuhanga bujyanye nabyo dushobora guhitamo neza igikoresho cyimashini ya CNC gikwiye mubikorwa byumusaruro nyirizina, tugakoresha neza ubushobozi bwacyo, kandi tugashyiramo imbaraga ninkunga ikomeye mugutezimbere gukomeye kwinganda zikora.